Colloidal Silica

PATSIL-30 is an alkaline, aqueous dispersion of colloidal silica which is about 30% by weight solids. The silica dispersion is stabilized with sodium, and the amorphous silica particles carry a negative surface charge. Silica particles are discrete, have a slightly rough, spherical shape and exist in a narrow particle size distribution. The physical appearance of the dispersion is a translucent liquid that is slightly more viscous than water.

Colloidal silica is a type of silica, a naturally occurring mineral suspended in a liquid medium. It is a highly pure substance and is used in a variety of applications, including abrasive, a reinforcing agent in rubber and plastics, and a component of paints and coatings. It is also used in the manufacture of ceramics, refractories and electronic components. Colloidal silica is highly stable and has excellent thickening and binding properties, making it a useful ingredient in many products.

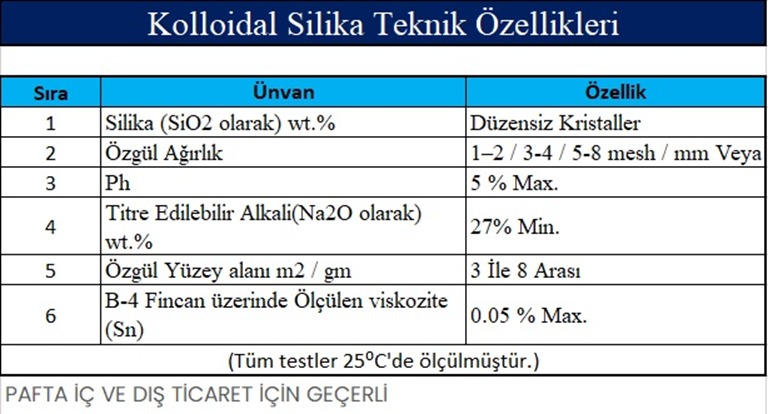

Features

Silica (as SiO2) by weight. % : 29-31

Specific Gravity: 1.20 – 1.25

pH : 9.5 – 10.5

Titratable Alkali (as Na2O) by weight. %: 0.300 – 0.600

Specific Surface area m2 / gm: 300 – 375

Viscosity Measured on B-4 Cup (Sn): 12.5-13.5

(All tests measured at 25oc)

Storage

PATIL-30 should be transported and stored at a temperature of 5-35 °C (40-95 oF). If the silica dispersion is allowed to freeze, silica precipitates irreversibly. For bulk storage, the tank must be sealed and made of plastic, glass fiber reinforced plastic or stainless steel. For packaged products, translucent packaging should be kept out of direct sunlight or bright light and not allowed to come into contact with oxygen/air.

Shelf life

The maximum shelf life of a colloidal silica product varies. Storing the product longer than its shelf life or in unfavorable conditions may affect the performance of the product. Avoid strong UV light as it can reduce shelf life due to organic growth. Maintain good hygiene during use to avoid bacterial contamination.

Under recommended conditions, PATIL – 30 has a shelf life of at least 120 days after manufacture.

APPLICATION

• Catalyst

* Concrete and Mortar

* Decorative Coating

* Insulation Coating

* Investment Casting

* Paper, Inkjet and Photograph

• Skins

• Pigment

* Refractory Materials

* Textiles and Fabrics

* Pulp and Paper

Function

* Binder for investment casting

* Anti-fouling in textile

* Anti-blocking in movies

* Scratch resistance for surface treatments and coatings

* Storage of paper fines

* Cement densification

* Anionic coagulant