- +90 216 912 14 74

- info@paftamuhendislik.com.tr

- Welcome to Pafta Mühendislik San. İç ve Dış Ticaret

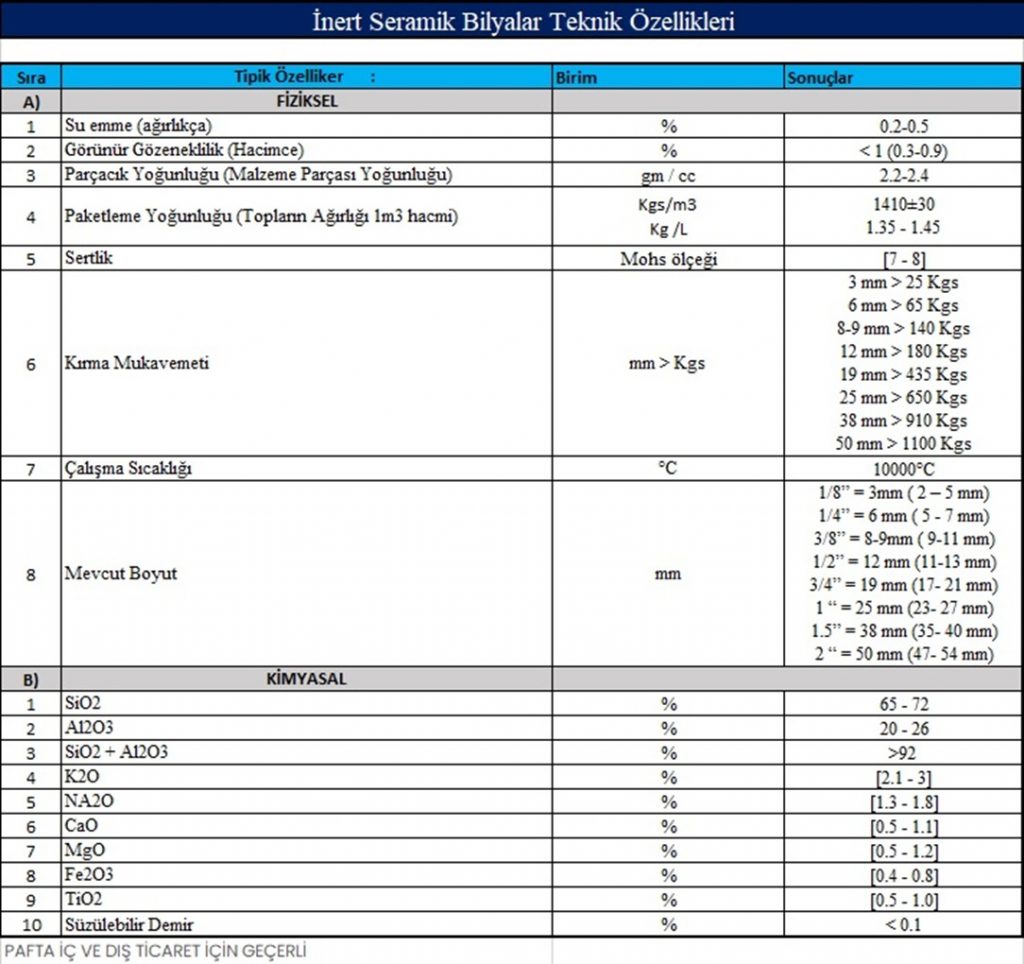

Inert Ceramic Balls are widely used in various chemical industries as bed support media for catalyst, adsorbent and dryers. With the most consistent physical properties, it is a good choice in bed support media for catalyst, adsorbents, molecular sieve and silica gel. The applied process consists of hydrotreating, hydrocracking catalytic conversion, catalytic oxidation, 3A molecular sieves for dehydration, 4A molecular sieves for natural gas drying or 5A molecular sieves for H2S and CO2 removal, desulfurization treatment, sulfur recovery units, etc. includes.

The primary role of inert alumina ceramic balls is to increase the gas and liquid distribution points. They also provide support and protection to the low strength activating catalyst.

They are excellent products used as coating and support materials in many industries. Available in many different sizes from 1.8 inches to 2 inches.

They have low water absorption rate and stable chemical properties. They can withstand high pressure and high temperatures, and also withstand the corrosion of alkali, acid and many organic solvents. Inert alumina ceramic balls withstand harsh temperatures.

Usage areas

Inert ceramic balls are widely used as catalyst and catalyst carrier in fertilizer, petrochemical and other industries. In addition to specific surface area and surface activity, carrier selection criteria include many other indicators, including mechanical strength, chemical stability and differential selectivity.

Whatsapp İletişim