- +90 216 912 14 74

- info@paftamuhendislik.com.tr

- Welcome to Pafta Mühendislik San. İç ve Dış Ticaret

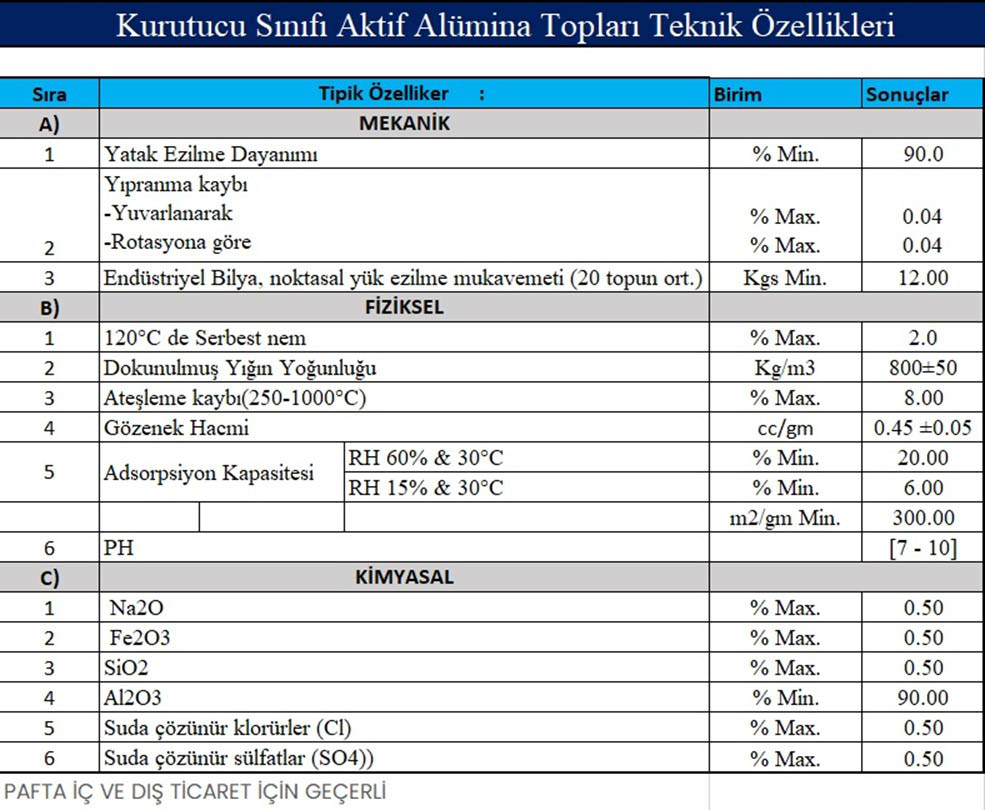

1. Dryer Grade Activated Aluminas

It is the perfect dryer for drying a wide variety of liquids and gases. Uniform ball size is particularly useful in high pressure gas dehydration where it is important to minimize the pressure drop and the special pore distribution provides high dynamic H2O adsorption capacity.

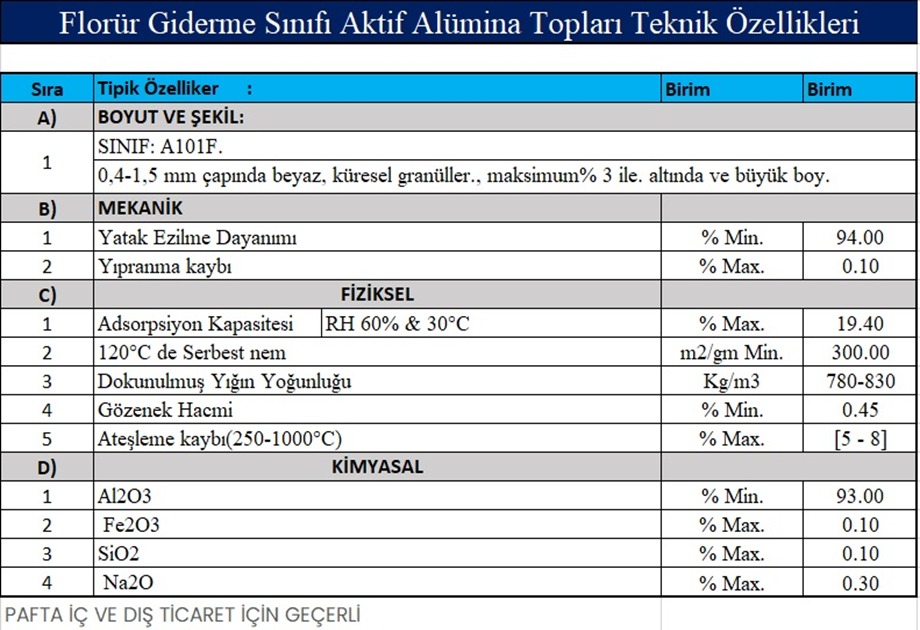

2- Fluoride Removal Grade Aluminas

• Lowest cost per 1,000 gallons due to high capacity and low cost per cubic foot. It is a solid material and does not deteriorate with backwashing.

• Works in a wide variety of water chemistry.

• Iron levels do not affect arsenic capacity.

• Disposable, disposable without any hazardous waste.

• Certified to NSF/ANSI standard 61 and successfully completed an EPA ETV project.

• It is an adsorbent for metals containing fluoride.

• Drinking water regeneration is normally used to operate at the most cost-effective levels.

• Fluoride grade is used to simultaneously reduce fluoride and arsenic to acceptable levels in a treatment.

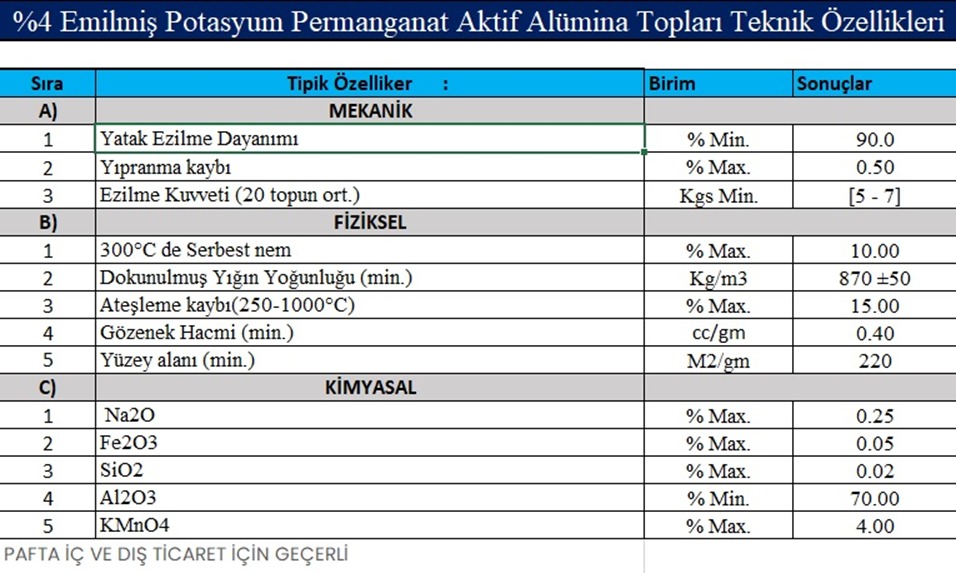

3- Absorbed Potassium Permanganate Aluminas

It is a spherical, active alumina-based medium impregnated with potassium permanganate (KMnO4). It is ideal for applications where activated carbon is ineffective, such as the adsorption of polar or low molecular weight compounds. Due to its spherical form it is suitable for use in various types of panel filters as well as in applications where lower pressure drop is required. The potassium permanganate concentration is higher than other similar products, thus providing a longer service life.

a. 4% KMnO4 Absorption:

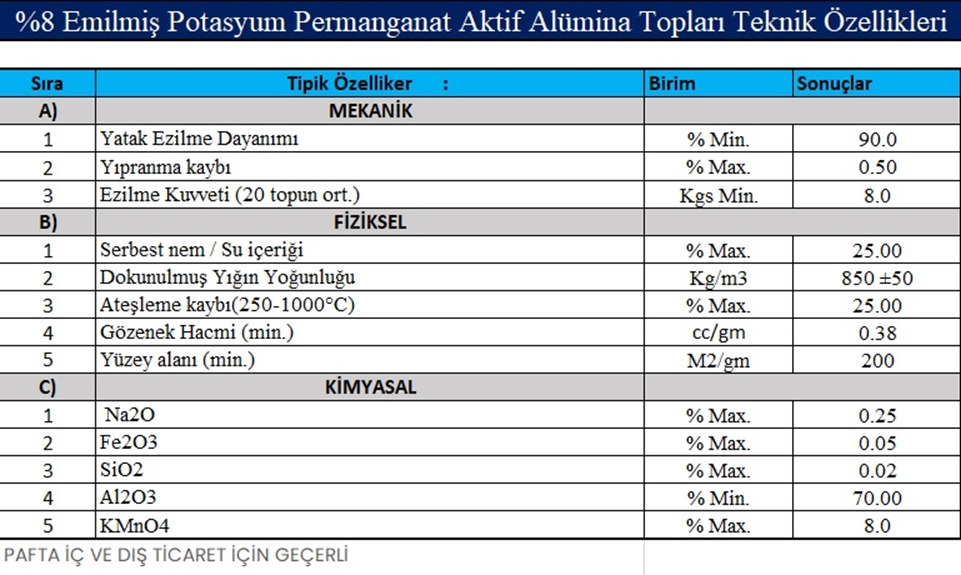

b. 8% KMnO4 Absorption

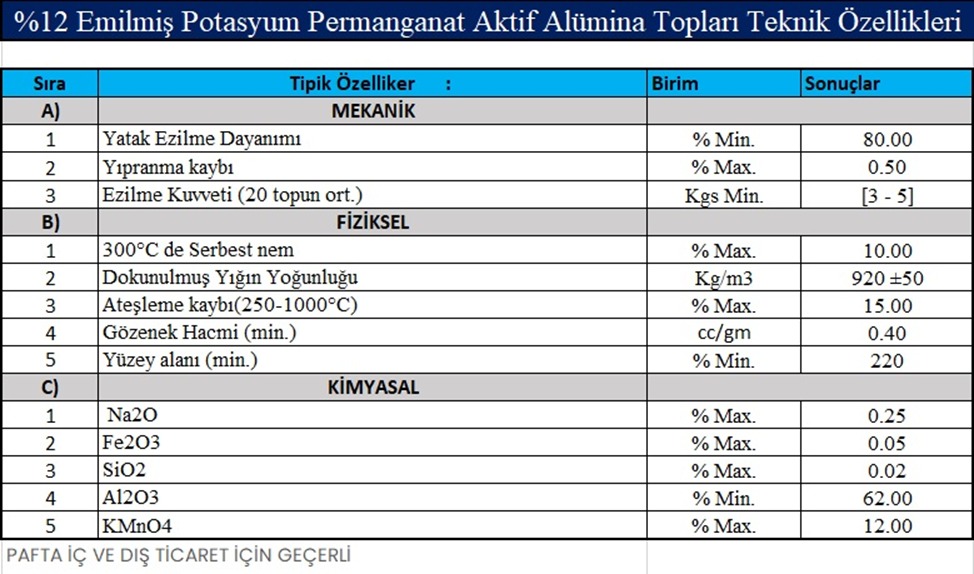

c. 12% KMnO4 Emilim

Whatsapp İletişim